Compressed Air Treatment

ies can provide you the necessary tools to obtain high quality compressed air, clean and dry, free of elements that can reduce efficiency and reliability of the system.

Dryers – ID

- Reduced energy consumption thanks to a careful selection of components and management by electronic board

- Low pressure drop thanks to the aluminum heat exchanger with a mixing chamber: air mixing increases exchanger efficiency and minimizes pressure drop

- Dew point maintained stable at 3°C under any conditions of use thanks to the work carried out simultaneously by both electronic board and heat exchanger with high efficiency

- ID dryers are equipped with electronic drain or programmable timer according to user needs

- Any other type of intelligent drain available upon request

- The only dryer on the market with a thermal protection

Oil Water Separator – WOS

WOS separator offers:

- High performances also for new synthetic oils for compressors, that cannot be separated from condensate by traditional ways, such as decantation

- Simplified maintenance and consequent reduction of maintenance costs

- Lower concentrations of oil, less than 10 ppm/l (by a regular replacement of bags)

- Compact dimensions and easy installation

- TWIN Solution, the only separators that can work by this particular combination with two or more separators

- Ecological and user-friendly material

- High reliability: innovative technology and high quality materials ensure high reliability and excellent performance

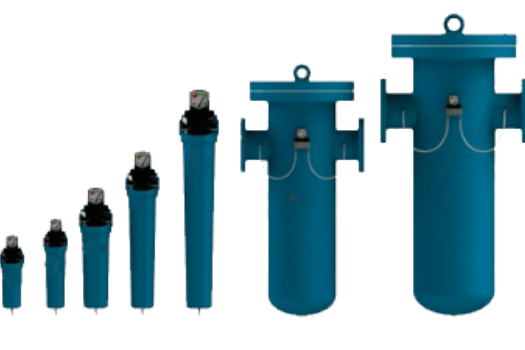

Filters – IF

Normally compressed air contains high concentrations of dust, oil, moisture and other impurities.These contaminants can lead to high-maintenance costs and result in damage to equipment and finished products. IF Filters have been specifically designed to prevent these problems, by offering a wide range of filters for compressed air able to satisfy the most various industry needs. The secret of IF is the high efficiency of the elements which is able to offer a high capability of retention (99,999%) and very low pressure drops. The final result is an extremely purified compressed air and low operating costs.

We supply a range of oil-free compressors from 1 to 5.3 HP. These can provide an optimal solution for use in settings such as dental laboratories, pharmaceutical laboratories, hospital institutes, chemical laboratories, industrial coatings.